Modulare Gesamtanlage

Traditionell werden Anlagen von GERLACH für die Herstellung von Dichtungsprofilen aus synthetischem Kautschuk in der Automotive-, Industrie,- Hochbau,- und Tiefbau Branche eingesetzt.

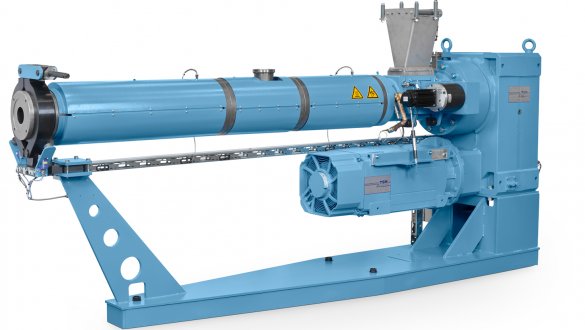

Extruder

Extruder Zum Lieferspektrum der Gerlach gehören kaltgefütterte Kompaktextruder, die entsprechend den Anforderungen unserer Kunden gebaut werden. Unsere Extruder verar- beiten Streifen- oder Granulatmischungen und können mit diversen Ausstattungsvarianten geliefert werden.

Vorschockeinrichtung

Schnelle Profil-Vorvernetzung auf kurzem Raum. Hierzu bieten wir gas- und elektrisch betriebene Maschinen mit unterschiedlichen Heizintensitäten sowie Modulationsmöglichkeiten an. Infrarot-, Gas-Keramik-, Fließbrenner sowie adaptierte Heißluftvorschocks. Die Maschinen sind für die Einfach- oder Mehrfachextrusion sowie als mobile eigenständige Maschinen konfigurierbar.

Schockkanäle

Insbesondere zur Effizienzsteigerung kommen modular aufgebaute kompakte 3 m Schockkanäle mit angetriebenen Rollen sowie mit und ohne Einlauftransportband zum Einsatz. Mittels Gasbeheizung werden Schocktemperaturen von bis zu 550 °C erzeugt. Das Energiekonzept berücksichtigt die Nutzung der Prozessluft im Umluftverfahren. Im Kanal turbulent strömende und beschleunigte Heißluft erzeugt den schnellstmöglichen Wärmeübergang.

Heißluftkanäle

Heißluftkanäle Als Haltestrecke, Trocknungs- oder Vulkanisationsmaschine sind unsere Maschinenserien des Typs HLK einsetzbar. Unser modulares Konzept bietet die Anlagekonfiguration ganz nach Ihren Wünschen. Ob im Frischluft oder im umweltfreundlichen Umluftverfahren mit Abluftreinigung, wir bieten für jeden Anspruch die richtige Konfiguration.

Mikrowellenkanäle

Mikrowellenkanäle Unsere kombinierten Hochleistungsschockkanäle vereinen die Leistungsfähigkeit aller Einzelmodule. Durch modulare Konfigurationen werden die Einheiten PreShock, Schockmodul, Mikrowellenzone und Heißluftzone in einem energiesparenden Wirkprinzip vereint. Durch die Integration der optional erhältlichen Abluftreinigung (PCT) erhalten Sie mit der Gerlach SHF Maschine ein umweltfreundliches und leistungsfähiges Gesamtkonzept.

Kühlkanäle

Geräuschreduzierte effektive Profilkühlung durch Spray, Schwall oder Tauchkühlung für flexible und starre Produkte. Modularer 3m Zonen-Aufbau, ausgestattet mit Transport-Rollenbahnen, mit oder ohne Abblasung sowie mobile Kühlkanäle mit und ohne Produkt-Transportband ergänzen unser Lieferprogramm. Standardmäßig sind unsere Kühlkanäle mit Wasserfiltern, Wärmetauschern und zum Einsatz in offenen oder geschlossenen Kühlkreisläufen bestens geeignet.

Ergänzungsmaschinen

Ergänzungsmaschinen Die Gerlach Maschinenbau GmbH bietet neben den Heißluftvulkanisationsanlagen auch Ergänzungsmaschinen rund um das Thema Gummi und Vulkanisationstechnik.

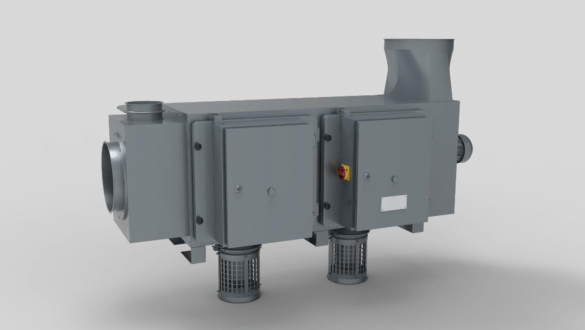

Abluftreinigung

Dämpfe, Gerüche und Schadstoffe, die bei der Vulkanisation entstehen, können erhebliche Auswirkungen auf Umwelt und Gesundheit haben und müssen deshalb neutralisiert und entsorgt werden. Gerlach bietet kompakte Lösungen, die bereits in die Maschinen integriert sind und autarke Abluftreinigungsanlagen, die z.B. an Altmaschinen oder Fremdmaschinen angeschlossen werden können.

Experts

Experts In unserer Rubrik Experts stellen wir Ihnen Sonderapplikationen, sowie Maschinen und Anwendungen aus dem Bereich der Forschung & Entwicklung vor.